Leading Tips for Inspecting Used Engines for Sale Before Buying

Leading Tips for Inspecting Used Engines for Sale Before Buying

Blog Article

Important Considerations for Ensuring High Quality and Long Life in Utilized Engines

When taking into consideration the purchase of a made use of engine, ensuring its high quality and longevity needs a multifaceted method. Maintenance background is a crucial factor, as it provides understanding into the engine's previous treatment and prospective future integrity. Beyond documentation, a comprehensive assessment of physical parts-- such as belts, tubes, and seals-- can disclose concealed problems. Efficiency testing is also critical, providing a snapshot of the engine's operational performance. Recognizing the nuances of these assessments and their implications can be intricate. What are the crucial approaches that can be employed to navigate this complex assessment procedure effectively?

Engine History Assessment

In the world of utilized engines, a thorough engine history analysis is vital to guaranteeing top quality and reliability. Understanding an engine's past can offer vital insights into its performance capacities and potential future long life. A thorough history evaluation incorporates numerous crucial facets that play a substantial function in evaluating an engine's condition. Firstly, maintenance documents are important. Routine maintenance, including oil changes, filter replacements, and scheduled tune-ups, suggest that the engine has been well-cared-for, lowering the possibility of unanticipated failings.

Engines that have gone through significant repairs may have underlying issues that could resurface. Analyzing the engine's mileage can offer as an indication of wear and tear. An engine made use of largely for long-distance freeway driving may be in far better condition than one subjected to regular stop-and-go city website traffic.

Basically, an extensive examination into an engine's background is crucial for making informed getting choices. used engines for sale.

Comprehensive Evaluation Overview

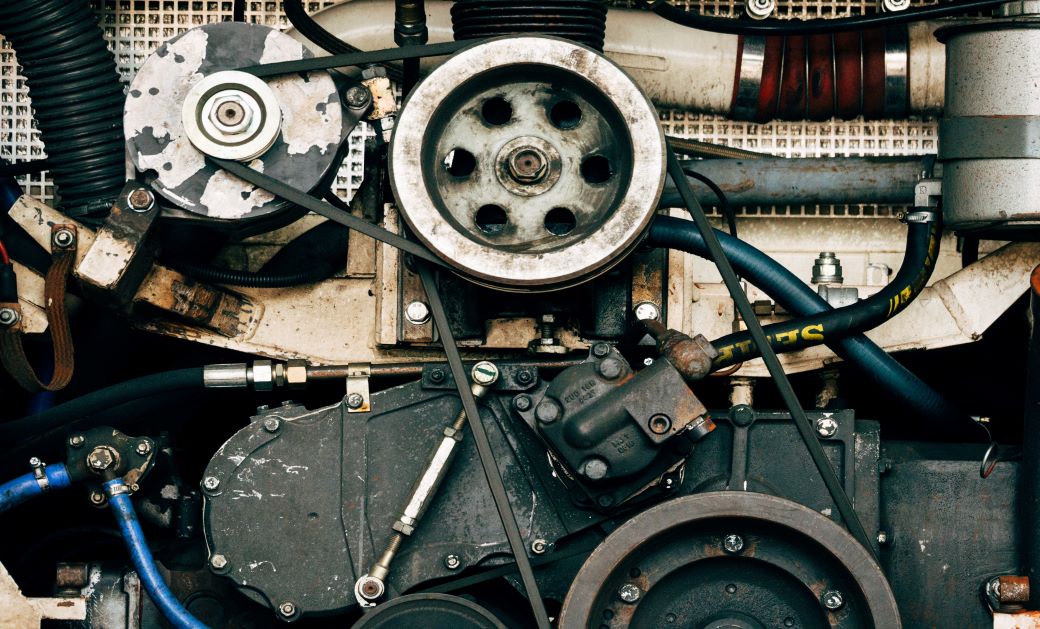

While understanding an engine's history provides useful context, an extensive evaluation is the following action to ensure its present condition lines up with historical data. The assessment needs to begin with a visual evaluation, inspecting for indicators of leakages, deterioration, and uncommon wear. Inspect the outside for oil discolorations or coolant marks, which might suggest underlying concerns.

Following, evaluate the engine's placing system for any type of loose screws or abnormalities that could impact efficiency. Pay very close attention to the condition of belts and hoses, as these elements are crucial for ideal engine functionality. Examine for cracks, fraying, or any signs of damage.

Identifying Put On and Tear

Acknowledging signs of damage is essential for evaluating a used engine's long life and integrity. It entails a meticulous evaluation of numerous engine elements to identify their current state and prospective future efficiency. Typical indicators include noticeable rust, which can affect steel components and jeopardize structural honesty. Rust on or around the engine block, cyndrical tube heads, and exhaust manifolds is specifically concerning.

An additional crucial element is inspecting the engine's seals and gaskets. These components are important for maintaining appropriate stress and protecting against liquid leakages. Proof of oil leakages or worn gaskets commonly suggests deterioration, potentially bring about more serious problems if not resolved quickly. Additionally, irregular sounds during engine operation, such as knocking or ticking audios, might indicate interior damages or extreme wear on relocating parts like pistons or bearings.

The condition of belts and pipes is equally important, as they play an essential role in the engine's general feature. Fractured or torn belts and weak pipes are indicators of maturing that can his explanation lead to engine failing if ignored. Taking a look at the oil problem and filter can supply understandings into previous maintenance practices, as dirty oil or blocked filters suggest neglect and increased wear.

Efficiency Testing Basics

Evaluating the wear and tear of engine parts establishes the phase for a thorough analysis through efficiency screening. Efficiency screening offers as a crucial procedure in figuring out the functional integrity of an utilized engine.

Using dynamometers is a common method in performance screening. These tools gauge the engine's output across numerous problems, supplying a comprehensive account of its capability. In addition, on-road testing enhances dynamometer assessments by observing engine behavior under normal driving scenarios, guaranteeing it satisfies the required standards for both safety and efficiency.

Advanced diagnostic devices further enhance the ability to pinpoint underlying concerns. These devices assess engine monitoring systems, determining faults in electronic components that can influence performance. Comprehensive screening not just confirms the engine's functional standing yet also aids in forecasting future upkeep demands. This makes certain the utilized engine can deliver reliable efficiency over an extended duration, hence optimizing its value and life span.

Upkeep and Treatment Tips

Appropriate upkeep and treatment are essential to lengthening the why not look here life expectancy of an utilized engine and guaranteeing its regular performance. Normal oil modifications are paramount; making use of the maker's recommended oil kind and grade can stop extreme deterioration. In addition, oil filters should be changed concurrently to keep ideal lubrication and tidiness within the engine.

Keeping track of fluid degrees, consisting of coolant, transmission liquid, and brake fluid, is important. Making sure these fluids go to ideal degrees assists protect against overheating and other mechanical concerns. Checking belts and tubes for indicators of wear, such as fractures or fraying, can avert prospective failures that may result in costly repair services.

Routine inspection of the air filter is likewise needed, as a clean filter ensures efficient airflow and combustion, consequently maximizing engine efficiency. Ignition system must be checked and replaced when needed to preserve efficient fuel burning and protect their website against engine misfires.

Last but not least, regular diagnostic checks using specialist tools can recognize potential problems prior to they end up being significant problems. By sticking to these upkeep and care suggestions, used engine proprietors can ensure their engines remain trusted, reliable, and efficient in performing more than a prolonged duration.

Final Thought

Report this page